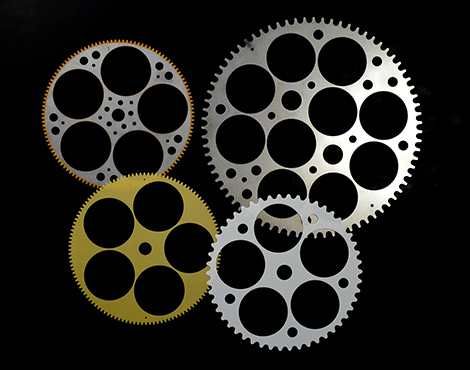

Our polishing carriers are called “cocoons” because they provide gentle protection like a real cocoon. They are used in the final polishing process on aluminum or glass substrates for hard disk drives and high-tech silicon wafers. We would be happy to make a proposal suitable for your application, such as single resin carrier and/or metal composite carrier.

Most collars used at the drive part to rotate a polishing carrier are made of metal or ceramics.

Those materials, however, cause friction, result in wear-and-tear and eventually damage

parts.

Just like the Cocoon, our collar provides excellent scratch resistance with low contaminant

concentrations. That is suitable for the polishing process, where minimizing scratches is the

key to the aluminum or glass substrates for hard disc drive and to the high tech silicon-wafer.

Absorbent table

Absorbent table

Carriage roller

Carriage roller

When producing liquid crystal display or plasma display, static

electricity generated by contact with jig and glass substrate tends to cause various issues such

as particle adherence, damage to TFT circuit, or increasing costs resulted from necessity of

installing more antistatic equipment.

In order to inhibit generation of static electricity rather than removing static electricity, we

have developed new materials that suppress peeling electrification against glass substrates.

Application: absorbent table, carriage roller, and absorbent pad. In case electrical

conductivity is required, the conductive grade is also available.