One of Fuji Bakelite’s biggest strengths is our integrated production system.

The system starts with a specification review and a technical proposal (planning) for the

customer.

It also includes mold design, mold manufacturing, injection molding, decorating, assembly,

processing and quality inspection.

This system provides high quality manufacturing and decoration as well as flexibility for delivery

and costs.

After receiving inquiry information from the customer, we use the reference drawings (for

quotation) to conduct an internal review of the specification from various perspectives,

including materials, strength, configuration, delivery and cost. Then, we provide a technical

proposal for the customer.

Each department offers ideas to ensure cost performance and a configuration that provides the

best quality. We focus on “Planning” that includes even more added value for the customer.

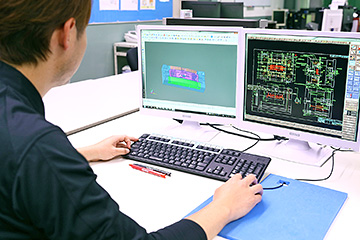

Plastic product quality is determined by the quality of the mold. We incorporate our expertise

into designing while taking in account the final processing and assembly and always staying

focused on the finished products.

We use internal factory manufacturing resources and external specialty manufacturers to make the

mold. We also use the latest CAD/CAM system and high performance machines to improve our

internal manufacturing.

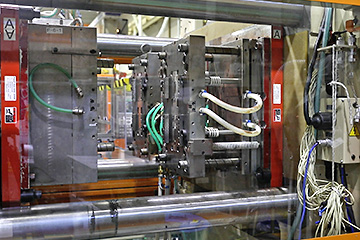

This injection molding is the foundation of the manufacturing process that produces precise

plastic molded parts. We adopt new technologies and methods and implement automation for

cutting-edge manufacturing.

By applying various molding technologies such as film insert, double-shot and weldless molding

and by using cutting-edge molding machines, we can produce precise molded parts for both strong

and intricate shape requirements.

This process features decorating technology focused on aesthetics and supports high-quality

design quality requirements for automotive parts. The process is a major point of distinction

from other companies, and we are constantly pushing the envelope with new decorating

technology.

Our strengths include coating technology such as piano black, finish high precision laser

etching technology and printing technology for clear text and marking.

Automotive components such as car audio and navigation systems are made of numerous parts with

intricate shapes. To complete the final product, parts are fitted together by hand.

We have processing equipment that automatically grinds and machines polishing carriers as well

as a special finishing machine that removes burrs from thermoset parts. We use unique, in-house

equipment for factory automation to ensure complete streamlining.

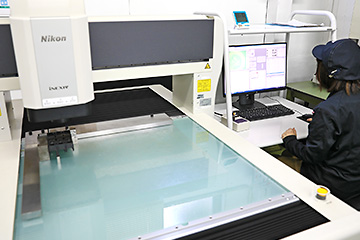

Quality assurance is one of the most challenging tasks as a manufacturer. Our system not only features cutting-edge machines but visual and other sensory checks to ensure that a complete quality assurance system is in place for every process. The latest inspection equipment and measuring instruments are used to measure color and gloss as well. Furthermore, we also consider the check process very important by way of performing visual, sound and tactile inspections on switch parts, etc.